Biomechanics and Bioengineering of Orthopaedics: Viscoelastic properties and nonlinear behaviour

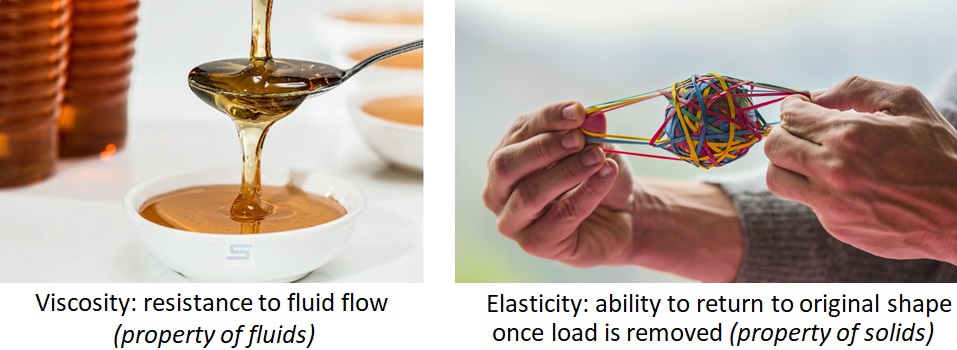

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. Generally, it is a resistance to fluid flow (Fig. 6-1). The deformation is not instantaneous and also not recovered.

Elasticity is a property of solids which is the ability to return to original shape once an applied load is removed (Fig. 6-1). Here we have Instant deformation under load and deformation is recovered.

Viscoelasticity is a combination of viscous and elastic behaviour. It is a property of some composite materials which makes them exhibit both viscous and elastic behaviour (Fig. 6-2). These materials are capable of undergoing deformation under tensile or compressive forces and although they return to their original state after removal of the force the viscous qualities make the deformation & return time dependent. Several examples in which nonlinear viscoelastic material behavior is relevant, range from biological to engineered systems.

Measuring mechanical properties

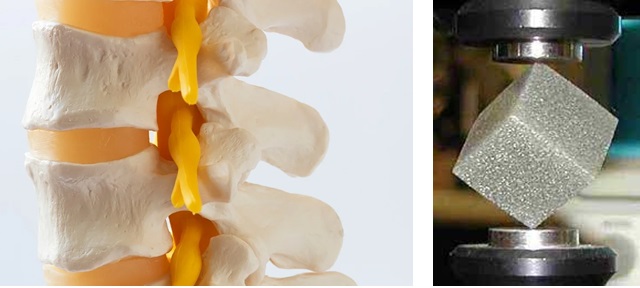

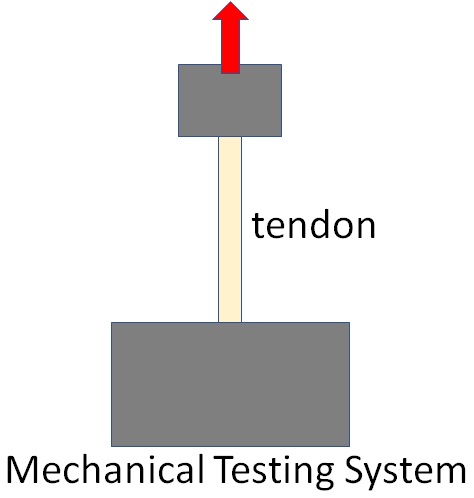

Now before we look at the key characteristics of viscoelastic materials let’s think about how they are measured; so for example we could have a piece of tendon in clamps in a mechanical testing device like the MTS; we apply a force to it and measure it’s properties in tension (Fig. 6-3).

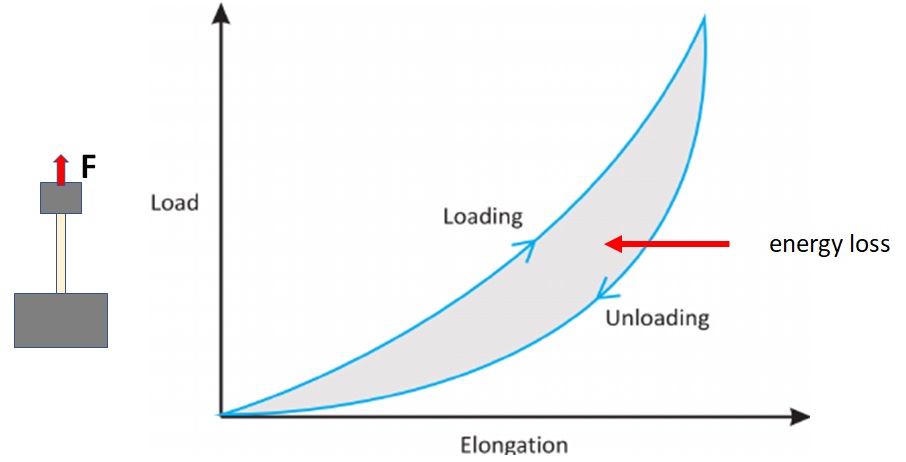

So as the tendon is loading and unloading, we notice the up curve is different from the down curve (Fig. 6-4). The region in the middle corresponds to energy lost. Not all of the energy gained due to lengthening is recovered during the shortening. Some energy is lost as heat. This phenomenon is known as hysteresis.

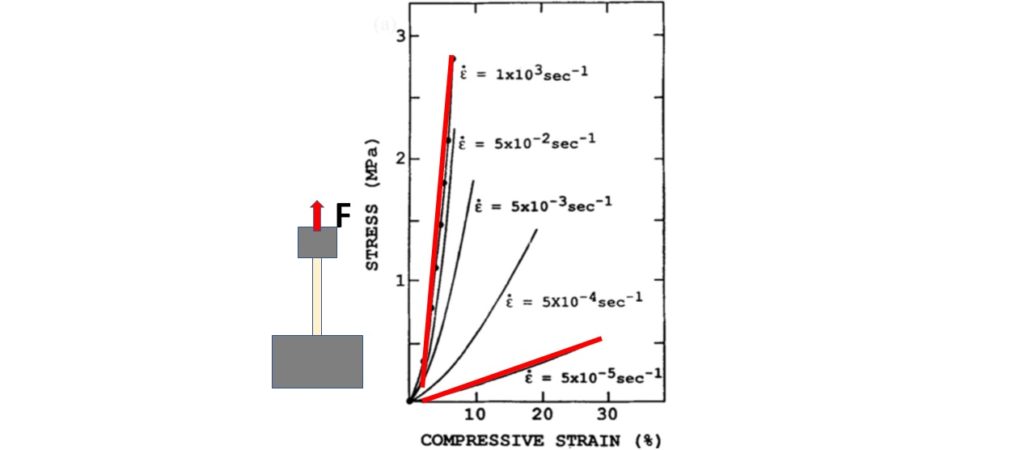

Also in loading viscoelastic materials we get different responses depending on how fast we load the material. In this graph example shown in Fig. 6-5, we have stress on the vertical axis and strain on the horizontal axis. If you load it quickly you end up with a steep slope and if you load it slowly you end up with a shallower slope. This phenomenon is known as rate-dependence, so the loading rate plays a role in how stiff the material would be.

Oloyede, A., Flachsmann, R., & Broom, N. D. (1992). The dramatic influence of loading velocity on the compressive response of articular cartilage. Connective Tissue Research, 27(4), 211224. Available from https://doi.org/10.3109/03008209209006997.

In an elastic material the stress (on the vertical axis) is linearly proportional to the strain (on the horizontal axis) and it is fully reversible (i.e., when the stress is removed, the material will return to its original shape, implying that the energy used to deform the material will be fully recovered in the inverse process to allow the object to return to its original shape.

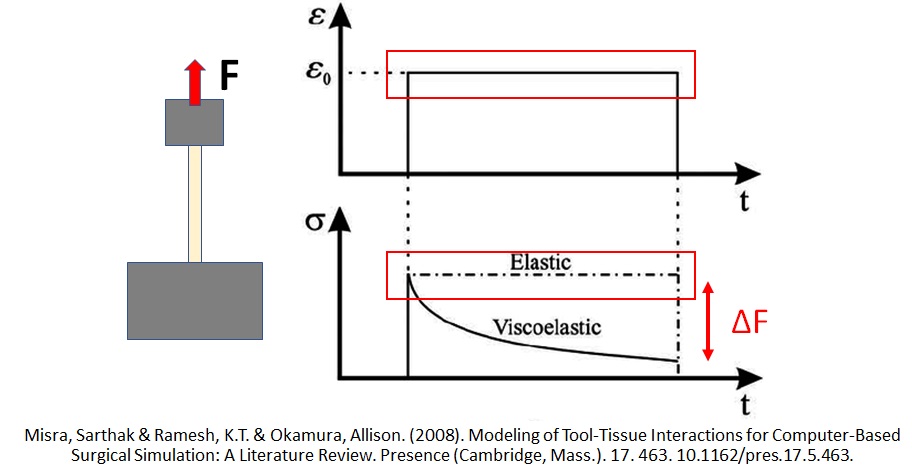

Now in the case of a viscoelastic material (Fig. 6-6); When we apply a set change in length to the tendon and measure the force or the stress overtime as you hold the length constant, we notice that the load drops off, there’s a change in force overtime, this is called stress relaxation.

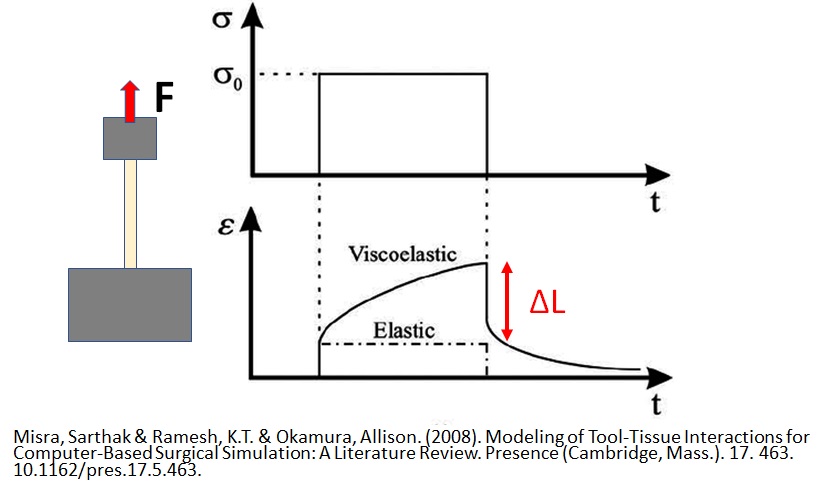

Also, If a set force is applied to a tissue and maintained at some level while the deformation or change in length produced by the force is measured, the deformation will gradually increase, and this phenomenon is known as creep (Fig. 6-7). So, essentially, we have a change in length as we hold the load constant.

Tissue components that contribute to viscoelastic behaviour

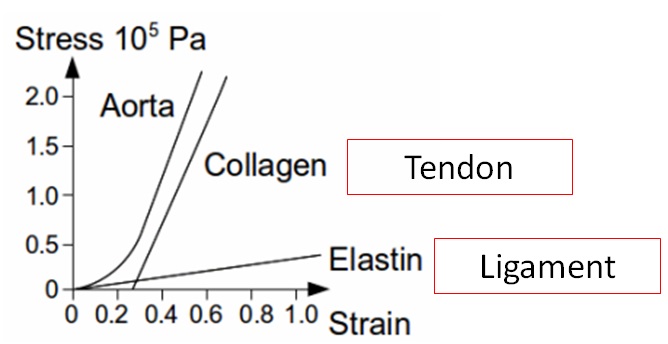

Different tissues contain different amounts of collagen and elastic fibres which are the tissue components that contribute to viscoelastic behaviour. The different amounts of these key components result in different mechanical properties. For example tendon has more collagen than elastin and Ligament has more elastin than collagen and these contribute to the mechanical behaviour we observe in these tissues (Fig. 6-8).

Fibre reinforced composite materials

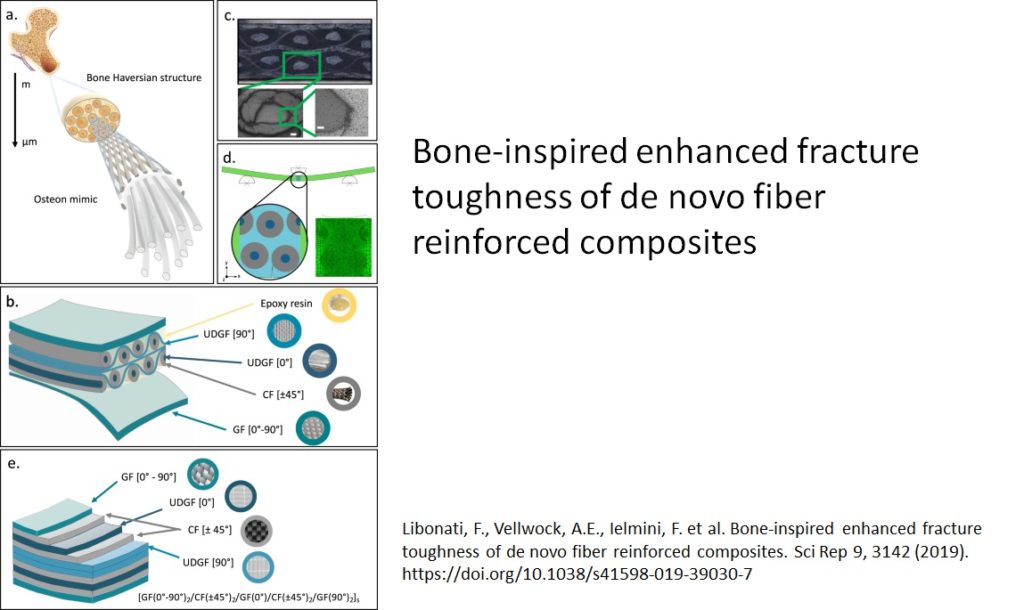

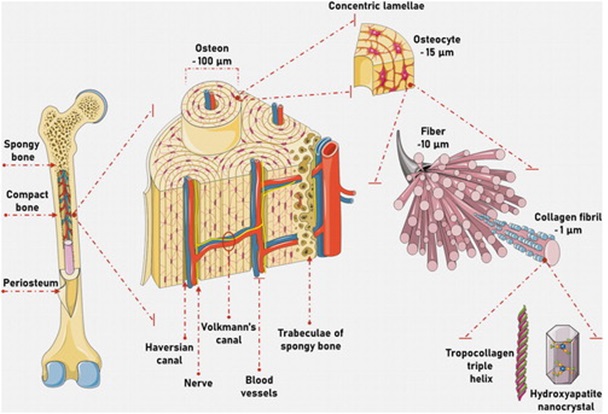

Natural bone is a complex composite material composed of an extracellular matrix of mineralized fibers containing living cells and bioactive molecules (Fig 6-9 ).

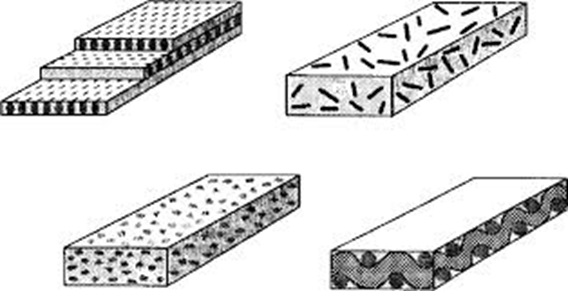

Consequently, we can use engineered fibers in biomaterial-based scaffolds to replicate the functional performance of bone. Fibre reinforced composite materials are composite materials which consist of fibres of significant strength and stiffness, embedded in a matrix (Fig. 6-10). Both fibres and matrix maintain their physical and chemical properties but together they perform a function that cannot be done by each constituent separately.

An example of fibre reinforced composite material is this enhanced de novo fiber reinforced composite (Fig. 6-11). This bioengineered structure was made with inspiration from the naturally occurring design of the bone haversian structure.