Stress: Other Measures of Stress

Engineering vs True Stress:

During material uniaxial tests, the value of the applied stress is obtained by dividing the applied force ![]() by the measured initial cross sectional area of the specimen

by the measured initial cross sectional area of the specimen ![]() . In this case, the stress is termed the “Engineering Stress”. If excessive decrease (or increase) in the cross sectional area occurs, then the force should be divided by the actual area

. In this case, the stress is termed the “Engineering Stress”. If excessive decrease (or increase) in the cross sectional area occurs, then the force should be divided by the actual area ![]() (area after deformation) to obtain the “True Stress”:

(area after deformation) to obtain the “True Stress”:

![]()

Similarly, the “Engineering Strain” as defined in uniaxial strain measures is obtained by dividing the elongation ![]() by the original length

by the original length ![]() , while the “True Strain” is obtained by taking the natural logarithm

, while the “True Strain” is obtained by taking the natural logarithm ![]() :

:

![]()

Considering the behaviour of metals, at higher strains, the deformation of a metal is volume preserving and thus:

![]()

In this case, the true stress is related to the engineering stress as follows:

![]()

Example:

The engineering stress vs. the engineering strain of a metal is given by the following table:

| Engineering Strain (%) | 0 | 0.1 | 0.2 | 0.4 | 0.5 | 1.0 | 2.0 | 3.0 | 4.0 |

| Engineering Stress(MPa) | 0 | 200 | 400 | 600 | 630 | 690 | 750 | 790 | 810 |

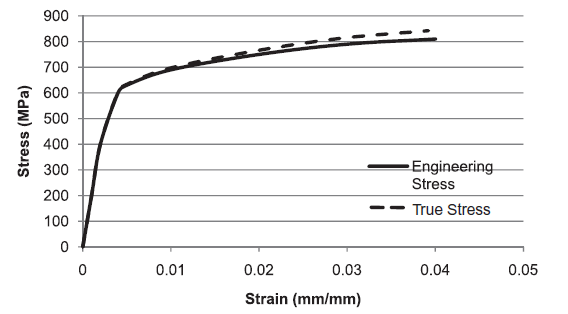

Compute the true stress and the true strain. Plot the engineering and the true stress vs. strain relationships.

Solution:

The following table is constructed using the equations for the true stress and true strain:

![]()

| 0 | 0.001 | 0.002 | 0.004 | 0.005 | 0.010 | 0.020 | 0.030 | 0.040 | |

| 0 | 0.001 | 0.001998 | 0.00399 | 0.004988 | 0.00995 | 0.0198 | 0.02956 | 0.0392 | |

| 0 | 200 | 400 | 600 | 630 | 690 | 750 | 790 | 810 | |

| 0 | 200.2 | 400.8 | 602.4 | 633.15 | 696.9 | 765 | 813.7 | 842.4 |

As shown in the plot below, the values of the true stress for metals are usually slightly higher than the values of the engineering stress for strains higher than 0.005.